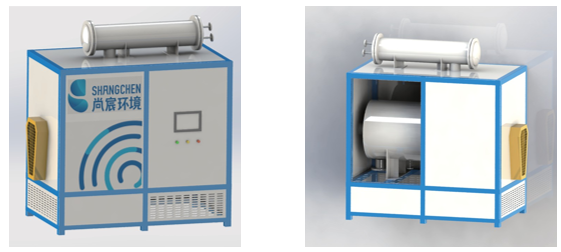

Integrated low-temperature evaporative water recovery equipment

RED Low-temperature Evaporation --- Drying Coupled Water Recovery Equipment

Shangchen RED low-temperature evaporation --- drying coupled water recovery equipment is a kind of continuous concentration and solidification integrated equipment developed for various kinds of high-salt wastewater, chemical waste liquid, high COD wastewater, and evaporation mother liquor.

The proprietary evaporation drying kettle structure design is not easy to scale, block and clean, and integrates the three unit operations of evaporation, drying and salt (sludge discharge) in one unit. It does not require a separate crystallizer, dryer or centrifuge, and can directly solidify and produce salt sludge or highly concentrated viscous materials.

Steam, hot water and heat transfer oil can be selected as heat sources, and heat exchange is carried out through jackets and rotating blades, with high thermal energy utilization rate.

It can effectively reduce the boiling point of the waste liquid by adopting low-temperature vacuum distillation technology, and features high evaporation efficiency. It can achieve high-multiple concentration and crystallization without greenhouse gas emission.

It adopts skid-mounted integrated design, and features compact and beautiful structure and small footprint. It starts with one-click, features intelligent operation monitoring, supports remote control and diagnosis, and operates stably and reliably.

Application field

It can be used for the reduction, concentration and drying of various kinds of high-salt and high-COD wastewater in industries such as chemical industry, electroplating, metallurgy, printing and dyeing, pharmaceuticals, new energy, machining, environmental protection and hazardous waste.

Main application scenarios: evaporation mother liquor, electroplating wastewater, electroplating tank liquid, surface treatment wastewater, machining emulsion, cutting fluid, cleaning wastewater, landfill leachate, RO membrane concentrated water, waste liquid for hazardous waste disposal, etc.

SEV Low-temperature Heat Pump Evaporative Water Recovery Equipment

Shangchen SEV low-temperature heat pump evaporative water recovery equipment relies on low-temperature evaporation technology to perform low-temperature evaporation and condensation of wastewater/waste liquid under vacuum conditions, thereby achieving gentle concentration and crystallization of wastewater/waste liquid; at the same time, it relies on air-energy heat pump technology to recycle heat and greatly reduce energy consumption. It is a new energy-saving and low-carbon product.

Shangchen SEV low-temperature heat pump evaporative water recovery equipment features compact structure, small land occupation and convenient assembly, and can be commissioned and operated by connecting to wastewater/waste liquid on site.

It features intelligent design, one-button start, fully automatic operation, and unattended operation.

Application field

Shangchen SEV low-temperature heat pump evaporator is widely used in emulsion wastewater, cutting fluid wastewater, electroplating wastewater, paint spraying wastewater, cleaning wastewater, high-salt wastewater, etc. It is especially suitable for small-volume wastewater in the electronic electroplating and machining industries.

Product Features

Ultra-low temperature evaporation

Shangchen SEV low-temperature hot pump evaporator maintains high vacuum to evaporate wastewater/waste liquid at room temperature as low as 30~37℃. For saline wastewater/waste liquid, low-temperature evaporation can greatly reduce corrosion to equipment. Low temperature is more suitable for heat-sensitive materials and materials prone to scaling.

High concentration, energy saving and high efficiency

According to different material characteristics, the amount of wastewater can be reduced by up to 90%~97%; heat pump technology is used to fully recover low-grade heat, and the comprehensive dehumidification ratio (SMER) is as high as 4.0kg·H20/kwh or more.

Evaporation Mother Liquor/High Concentration Waste Liquid Evaporative Water Recovery Equipment

During the process of zero discharge of wastewater or evaporation and crystallization of saline wastewater, with the enrichment of impurity ions, high-boiling point substances, organic matter and other components in the mother liquor, the quality of the crystallized salt will decline or even the salt will not be crystallized, the evaporator will be seriously blocked, the evaporation capacity will decrease, the MVR steam compressor will vibrate violently and surge frequently, resulting in the evaporator being unable to continue operating. Therefore, many companies will discharge a small amount of evaporation mother liquor to maintain the balanced, continuous and stable operation of the evaporation system. The treatment of this part of evaporation mother liquor has always been a difficult problem for enterprises. Most enterprises outsource the disposal of evaporation mother liquor as hazardous waste, which greatly increases the burden on enterprises. The treatment of evaporation mother liquor has also become the key to achieving true zero discharge of wastewater from saline wastewater.

Evaporation mother liquor/high-concentration waste liquid to be treated

The water quality of the evaporation mother liquor is complex, usually with a very high salt concentration (TDS - generally above 20%) and a very high COD (generally above 100,000 mg/L), and it has the characteristics of strong corrosiveness, high viscosity, and high boiling point.

Currently, the treatment equipment for evaporation mother liquor/high-concentration waste liquid on the market includes single-effect evaporator, drying equipment, incineration equipment, etc., which have many problems such as high operating cost, easy corrosion of equipment, short life, and complex operation and maintenance. In response to the current situation in the industry, Shangchen has developed and launched special evaporation water recovery equipment for evaporation mother liquor/high-concentration waste liquid. It uses proprietary technology to solve the problem of evaporation mother liquor/high-concentration waste liquid disposal at a low cost.

Product Solution

The evaporation mother liquor/high-concentration waste liquid is first sent to the customized pretreatment system (optional) to remove suspended solids, COD, hardness or other substances that are not suitable for entering the evaporator, and then sent to Shangchen's special evaporator for evaporation mother liquor/high-concentration waste liquid. After evaporation concentration, crystallization or drying, recycled water, crystallized salt or solidified salt sludge are finally obtained.

There are two recommended solutions for Shangchen special evaporator for evaporation mother liquor/high-concentration waste liquid:

① For mother liquor/high-concentration waste liquid that is easy to crystallize, it is recommended to adopt Shangchen ultra-high temperature rise skid-mounted UltraMVR evaporative water recovery equipment;

② For mother liquor/high-concentration waste liquid that is not easy to crystallize, easy to coke, or has poor fluidity, it is recommended to adopt Shangchen RED low-temperature evaporation-drying coupled water recovery equipment.

Shangchen Ultra-high Temperature Rise Skid-mounted UltraMVR Evaporative Water Recovery Equipmentit is a proprietary high-temperature rise MVR technology developed on the basis of the standard skid-mounted ModMVRevaporator. It can increase the secondary steam temperature to 60'c, thereby concentrating and crystallizing high-boiling pointmaterials such as evaporation mother liquor and high-concentration waste liquid at a low cost.

The temperature rise of up to 60C means that more concentrated materials with higher boiling points can be processedwithout oroblems such as ow evaporation. compressor suroe and inabilitvy to crystalize salt due to insufficient heaexchange temperature difference.

The HRMVR eneroy-saving technoloay is adooted. and the operating cost per ton of water is as low as 50-80 yuan, whichhas obvious operating cost advantages.

it is made of titanium alloy etc., which is resistant to salt corrosion, and features long service life, stable and reliableoperation.

Shangchen RED Low-temperature Evaporation --- Drying Coupled Water Recovery EquipmentThe low-temperature vacuum distilation technology can effectively reduce the boiling point of the waste liquid. lt is a kind ofintegrated continuous concentration and solidification equipment developed for various evaporation mother liquors/high-concentration waste liquids that are difficult to crystallize, easy to coke, or have poor fluidity.

lt is subject to proprietary evaporation drying ketle structure design, not easy to scale, coke and blockage, and is easy toclean.

lt integrates the three unit operations of evaporation, drying and salt (sludge) discharge into one unit. It can directly solidifyand produce salt sludge or highly concentrated viscous material without the need for separate crystallizers, dryers anccentrifuges.

Steam, hot water, and heat transfer oil can be selected as heat source, and heat exchange is carried out through jacketsand rotating blades, with high thermal energy utilization.

it adopts skid-mounted inteqrated desicn. which is compact, beautiful and occupies litle space: it starts up with one buttonhas intelligent operation monitoring, supports remote control and diagnosis, and operates stably and reliably.

Evaporative Water Recovery Equipment for Emulsified Mixture/Cutting Fluid

The core part of Shangchen evaporative water recovery equipment for emulsified mixture/cutting fluid is Shangchen SEV low-temperature heat pump evaporator, which relies on low-temperature evaporation technology to perform low-temperature evaporation and condensation of emulsion cutting fluid, cleaning water and other wastewater under vacuum conditions to achieve gentle concentration of wastewater; at the same time, it relies on air energy heat pump technology to recycle heat and greatly reduce energy consumption. It is a new energy-saving and low-carbon product.

The core part of Shangchen evaporative water recovery equipment for emulsified mixture/cutting fluid is Shangchen sEV ow-temperature eat pump evaporator. which relies on ow-temperature evaporation techno opy to perormlow-temperature evaporation and condensation of emulsion cutting fuid, cleaning water and other wastewater undervacuum conditions to achieve gentle concentration of wastewater, at the same time, it relies on air energy heat pumptechnology to recycle heat and greatly reduce energy consumption. it is a new energy-saving and low-carbon product

Product Solution

Wastewater such as emulsified mixture, cutting fuid, and cleaning water first passes through an oil residue separatorto remove grease, suspended matter and other substances, and then is vacuum-absorbed into the Shangchen sEylow-temperature heat pump evaporator after passing through a transfer tank, After low-temperature evaporation andhigh-multiple concentration.recvcled water and a very mal amount ol concentrated lauid are finally obtained

Scope of Application

Shangchen emulsified mixture/cutting fuid evaporator is suitable for the following fields or similar types of salt-con-taining wastewater: emulsion/metalworking fluid, die-casting industry rubber mold emulsified mixture, cuting wastefuid, printing waste fluid, rolling waste fuid/eveling fluid, quenching fluid wastewater, electroplating wastewater/sur.face treatment wastewater/heavy metal waste water, electroplating tank liquid/aging fluid, waste liquid that needs to beouisourced, degreasing cleaning waste liquid, cleaning water lor cleaning parts, cleaning water lor paint pretreatmentcleaning water for electroplating, cleaning water for heat treatment workshops, cleaning water for stainless steepickling, cleaning water for faw detection, cleaning water for cleaning containers, and cleaning water for grinding.

Guangdong Shangchen Environmental Technology Co., Ltd. is a large-scale technology-based comprehensive service provider of resource recycling. Shangchen is devoted to the field of industrial wastewater and has become a leading role in the industry after more than ten years of rapid development. The core business of the Company is concentrated in the field of industrial wastewater treatment, and covers pollution control fields such as river management, pyrolysis of domestic waste, heavy metal soil management, sludge reduction, waste acid and alkali recovery, and hazardous waste treatment. Shangchen is committed to providing customers with professional overall solutions, and has now formed a complete industrial chain of environmental pollution control throughout the entire life 。

1、Integrated Waste Alkali Recovery Equipme

2、Integrated Waste Acid Recovery Equipment

3、Integrated Sludge Drying Equipment

4、Integrated low-temperature evaporative w

5、Integrated HEMVR Evaporative Water Recov

6、Integrated special membrane water recove