Integrated Waste Acid Recovery Equipment

Integrated Waste Acid Recovery Equipment

Industrial waste acid or acidic wastewater is mainly produced in the processes of nitration, esterification, sulfonation, alkylation, catalysis and gas drying of organic matter, or in the processes of titanium dioxide production, steel pickling, etc. It is mainly from petroleum and petrochemical, titanium dioxide, coatings, inks, steel, electronics, metal surface treatment and other industries.

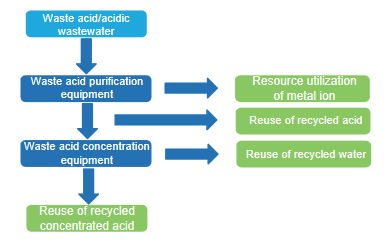

Shangchen integrated waste acid recovery equipment is mainly used for the purification and concentration of industrial waste acid (including waste sulfuric acid, waste hydrochloric acid, waste phosphoric acid, etc.) or acidic wastewater, helping acid-using enterprises to reuse waste acid or utilize waste acid as a resource.

Shangchen integrated waste acid recovery equipment includes two modules: waste acid purification and recovery equipment and waste acid concentration and recovery equipment. Customers can choose according to actual demands.

Waste acid purification and recovery equipment

By using special acid-resistant metal ion membrane separation technology, suspended solids, organic matter and metal ions in waste acid can be removed to obtain purified recycled acid solution (which can be further extracted to achieve metal resource recovery).

Waste acid concentration and recovery equipment

The recycled acid obtained from the waste acid purification equipment is concentrated using special acid-resistant membranes and low-temperature evaporation technology to obtain concentrated acid and distilled water.

Product Features

High acid recovery rate

The special acid-resistant metal ion separation membrane is adopted for acid purification, with the acid recovery rate exceeding8596

The recycled acid has high concentration

The integrated acid purification equipment can separate acid and salt within 25% acid concentration: after concentration by theintegrated acid concentration equipment, 30-65% sulfuric acid, 15-25% hydrochloric acid or 60-85% phosphoric acid can beobtained according to customer demands, and the recycled acid has high concentration.High operating stability

The integrated waste acid recycling equipment can effectively eliminate the industry problem of crystalization blockage of wasteacid evaporator by adopting proprietary technology, and features stable and reliable operation.The recycled acid has high purity

The integrated acid purification equipment has a metal impurity ion removal rate of more than 95%. The recycled acid basicalldoes not contain metal ions. The recycled acid has high purity and good quality. It wil not cause any harm to the production ifit isreused in production.

Guangdong Shangchen Environmental Technology Co., Ltd. is a large-scale technology-based comprehensive service provider of resource recycling. Shangchen is devoted to the field of industrial wastewater and has become a leading role in the industry after more than ten years of rapid development. The core business of the Company is concentrated in the field of industrial wastewater treatment, and covers pollution control fields such as river management, pyrolysis of domestic waste, heavy metal soil management, sludge reduction, waste acid and alkali recovery, and hazardous waste treatment. Shangchen is committed to providing customers with professional overall solutions, and has now formed a complete industrial chain of environmental pollution control throughout the entire life 。

1、Integrated Waste Alkali Recovery Equipme

2、Integrated Waste Acid Recovery Equipment

3、Integrated Sludge Drying Equipment

4、Integrated low-temperature evaporative w

5、Integrated HEMVR Evaporative Water Recov

6、Integrated special membrane water recove