Integrated Sludge Drying Equipment

Sludge dewatering equipment such as sludge dewatering screw press, belt filter presses, plate and frame filter presses can generally reduce the sludge moisture content to 60~85%. Shangchen integrated sludge drying equipment can further reduce the sludge moisture content to 10~40% (depending on customer demands), reduce the volume, and thus greatly reduce the sludge disposal cost. The dried sludge can be disposed of (comprehensive utilization of fertilizer, soil conditioner, alternative energy, building materials, etc.) in conjunction with power plants, cement plants, waste incineration plants and landfills based on the surrounding conditions.

Application Field

it can be widely used for reduction of municipal sludge and industrial sludge (in industries of chemical, electroplat ing, printing and dyeing, leather, papermaking, pharmaceuticals, etc.)

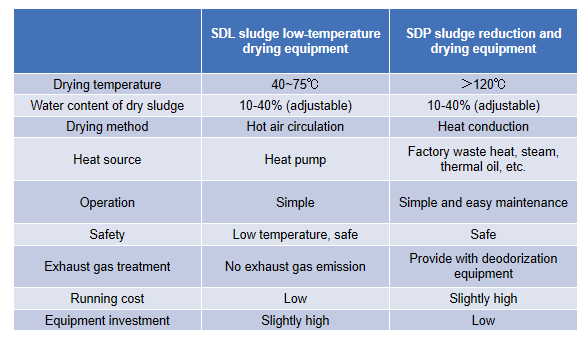

Product Classification

Shangchen integrated sludge drying equipment currently has two models: SDL low-temperature sludge drying equipment and SDP sludge reduction drying equipment, and users can choose according to actual demands.

SDL Sludge Low-temperature Drying Equipment

Shangchen SDL sludge low temperature drying equipment follows the principle of low temperature dehumidification heat pump and adopts convection hot air circulation drying method to dehydrate and dry the wet sludge on the mesh belt. The drying process recovers the latent heat of water vapor and sensible heat of air in the exhaust air without any waste heat emission.

Product Features

Eficient reduction

The moisture content of dry sludge can be as low as 10-40%, and the sludge reduction can be as high as 80% or more, greatlysaving a lot of subsequent transportation costs and treatment costs.

Low consumption and energy saving

It adopts a closed system design with no waste heat emission; it relies on multi-effect dehumidification heat pump technology, withthe comprehensive dehumidification ratio (SMER) of up to 4.2kg H20kwh or more. When the wet sludge with a moisture content ot80% is dried to a moisture content of 30%, the operating cost is as low as 170kwh/T

Intelligent operation

Integrated structural design, simple and convenient installation; fully automatic operation, PLC+touch intelligent control, remote

centralized control can be realized.

Odorless and zero emissionFully enclosed structure, no odor leakage, no need to install additional deodorizing equipment.Low temperature. safer

it works at a low temperature of 40-75'C. with no risk of dust and exolosion, The dischare sludge temperature is lower than 50Cand can be stored directly.

SDP Sludge Reduction and Drying Equipment

Shangchen SDP sludge reduction and drying equipment adopts hollow blades and hollow sandwich structure for indirect heating, which has a higher heat transfer area and material volume ratio. Furthermore, the blades are designed to resist sludge adhesion, thus ensuring efficient and stable thermal efficiency.

SDP sludge reduction and drying machine is easy to operate, maintain and has low equipment investment.

SDP sludge reduction and drying equipment can be equipped with factory waste heat, steam, heat transfer oil, etc. as drying heat sources according to the site conditions of the customer. Dry sludge does not need to be back-mixed, and the moisture content of the outlet sludge can be adjusted by the rotation speed of the shaft, so it can be fully dried or semi-dried. The particle size of fully dried sludge particles is generally less than 10mm, and semi-dried sludge is generally loose and clumpy. It can be widely used in the reduction treatment of municipal sludge and industrial sludge.

Product Features

Efficient reductionThe mechanically dehydrated sludge with moisture content of 75-85% can be directly dried to 10%. and the reduction can reachmore than 80%, which can save a lot of later transportation costs and disposal costs.Load is adjustable

The transmission and feeding motors adopt variable frequency stepless speed regulation. The visible sludge with different moisturecontent (60-85%) can be fed continuously, and dry sludge with different moisture content (10-40%) can be obtained. It has strongadaptability, large operational flexibility and high drying efficiency.Ecofriendly and odorless

There is no large amount of air carying heat, no high concentraion of dust is generated, and no greenhouse gas emissions:it isequipped with necessary dust removal and deodorization equipment, and the exhaust gas meets the relevant emission requirementssuch as the "Emission Standards for Odor Pollutants".

Guangdong Shangchen Environmental Technology Co., Ltd. is a large-scale technology-based comprehensive service provider of resource recycling. Shangchen is devoted to the field of industrial wastewater and has become a leading role in the industry after more than ten years of rapid development. The core business of the Company is concentrated in the field of industrial wastewater treatment, and covers pollution control fields such as river management, pyrolysis of domestic waste, heavy metal soil management, sludge reduction, waste acid and alkali recovery, and hazardous waste treatment. Shangchen is committed to providing customers with professional overall solutions, and has now formed a complete industrial chain of environmental pollution control throughout the entire life 。

1、Integrated Waste Alkali Recovery Equipme

2、Integrated Waste Acid Recovery Equipment

3、Integrated Sludge Drying Equipment

4、Integrated low-temperature evaporative w

5、Integrated HEMVR Evaporative Water Recov

6、Integrated special membrane water recove