Treatment of Fine Chemical Refractory Wastewater --- Key Processes and Methods

What is fine chemical refractory wastewater treatment?

Fine chemical refractory wastewater treatment refers to the treatment of refractory wastewater in the fine chemical industry to reduce environmental pollution and protect water resources. This type of wastewater usually contains complex organic compounds, heavy metals and other pollutants, which conventional treatment methods are difficult to effectively remove these components, so it will increase the difficulty of treating this type of wastewater.

Core of fine chemical refractory wastewater treatment

According to the Large suspended solids can be removed through physical methods such as screening and sedimentation, thus reducing the burden of subsequent treatment.

① Pretreatment

Large suspended solids can be removed through physical methods such as screening and sedimentation, thus reducing the burden of subsequent treatment.

②Physical and chemical treatment

Remove pollutants from wastewater by methods such as chemical precipitation, adsorption, oxidation etc. For example, degrade refractory organic matter by adopting advanced oxidation processes (AOPs).

③Biological treatment

Decompose organic matter with microorganisms, which is suitable for some biodegradable pollutants. The activated sludge method, sequencing batch reactor (SBR), etc. can be adopted.

④Membrane separation technology

Further remove the residual pollutants through membrane technologies such as ultrafiltration, nanofiltration or reverse osmosis, thus improving the water quality.

⑤Concentration and disposal

Concentrate the treated wastewater to extract useful components or reduce its volume, and conduct innocent treatment for the residual sludge.

⑥Monitoring and control

Monitor the water quality parameters in real time with online monitoring system, ensure that the treatment effect meets the emission standards.

[Shangchen Environment - Engineering Cases]

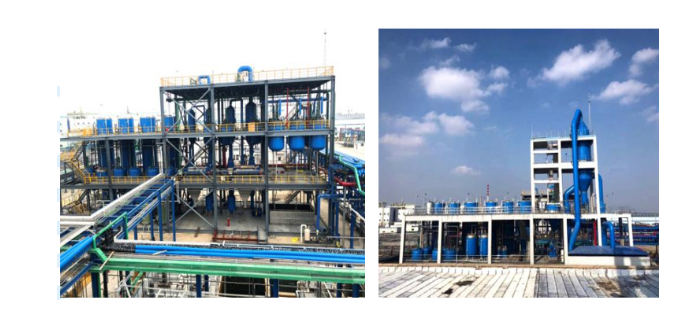

[Chemical Wastewater Treatment Project of Jiangsu Wuzhong Henglida Technology Co., Ltd.]

The process wastewater of Henglida dyes and dye intermediates has high content of organic matter and inorganic salts. The salt content is 20%-30%, mainly containing sodium sulfate, ammonium sulfate, ammonium chloride and incompletely separated naphthalenesulfonic acid, nitro organic compounds, hydrocarbon radicals and other organic intermediates. According to the characteristics of the wastewater of this Project, a gradual and step-by-step extraction method is adopted for treatment.

The wastewater is first subjected to extraction treatment to reduce COD and remove organic matter. The oil phase obtained after extraction contains a large amount of organic matter and a small amount of salt. After being concentrated by secondary evaporation, the obtained organic matter is returned to the workshop. The COD of the extracted water phase is reduced from 50,000-70,000 mg/l to below 8,000 mg/l before MVR evaporation. The wastewater containing sodium sulfate or sodium chloride is precipitated during the evaporation process and sold as a by-product after centrifugal separation and washing. The COD and salt content of the MVR distilled water can reach below 500 mg/l before being further treated in the biochemical and subsequent units.

The wastewater extraction technology of Shangchen Environment is the most advanced technology in the industry, with the characteristics of high efficiency and selectivity, easy stripping and solvent regeneration, little secondary pollution, and low operating costs. MVR evaporation is an energy-saving technology equipment strongly recommended by China, and its operating cost is only 1/2 to 1/3 of that of traditional evaporators. Shangchen Environment adopts this combined treatment method to solve the wastewater treatment problem in the production of dyes and dye intermediates, while maximizing the resource utilization of wastewater. The comprehensive treatment cost is greatly reduced compared with the treatment cost of traditional treatment processes.

Guangdong Shangchen Environmental Technology Co., Ltd. is a large-scale technology-based comprehensive service provider of resource recycling. Shangchen is devoted to the field of industrial wastewater and has become a leading role in the industry after more than ten years of rapid development. The core business of the Company is concentrated in the field of industrial wastewater treatment, and covers pollution control fields such as river management, pyrolysis of domestic waste, heavy metal soil management, sludge reduction, waste acid and alkali recovery, and hazardous waste treatment. Shangchen is committed to providing customers with professional overall solutions, and has now formed a complete industrial chain of environmental pollution control throughout the entire life 。

1、Watershed Management and Ecological Rest

2、Integrated River Management - Project Sc

3、How to achieve zero discharge of desulfu

4、High-salt Organic Wastewater Treatment -

5、Acidic Wastewater Treatment and Resource

6、Treatment of Fine Chemical Refractory Wa