What are the core steps of industrial wastewater zero discharge?

With the acceleration of industrialization, industrial wastewater discharge

poses a serious threat to the ecological environment. Zero discharge of

industrial wastewater has not only become a key link in environmental

protection, but also an important force in promoting the green transformation of

the economy.

According to the national standard GB/T21534-2008 "Industrial Water Usage And Conservation --- Terminology", [zero discharge] is defined as "the production water system of an enterprise or main unit achieves zero industrial wastewater discharge."

So what are the core steps of industrial wastewater zero discharge?

The core steps of industrial wastewater zero discharge mainly include:

1. Wastewater pretreatment

The wastewater is initially treated to remove large particles or easily treatable pollutants through screens, sedimentation tanks and other equipment.

2. Concentration and evaporation

The wastewater is concentrated through reverse osmosis and other technologies, and most of the dissolved substances in the water are separated, separating the clean water and high-concentration brine that can be reused. The residual water is then evaporated with evaporation device to precipitate solid salt.

3. Crystallization recovery

The concentrated brine after evaporation is further crystallized, and the dissolved salts or other solid substances in the concentrated solution are separated by crystallization to form reusable solid waste. For some wastewater containing valuable heavy metals or rare elements, they can also be extracted and recovered through ion exchange, adsorption and other methods.

4. Recycled water treatment

The evaporated water can be further treated and then reused in the production process.

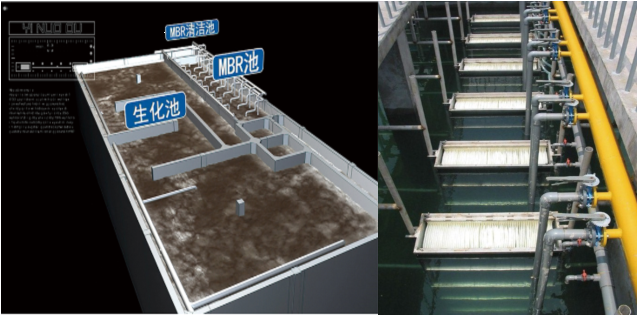

With own core patented technology of "zero discharge" for metal industrial wastewater, through the technical route of "wastewater diversion, classification treatment, wastewater reuse, and resource recovery", by adopting the combined process of "heavy metal high-precision removal pretreatment + OSMMBR biochemical technology + SPNR technology + MVR crystallization technology" of Shangchen Environment, all the treated heavy metal wastewater are used for production, the wastewater reuse rate is increased to 99.6%, which maximized the recycling of water resources.

Guangdong Shangchen Environmental Technology Co., Ltd. is a large-scale technology-based comprehensive service provider of resource recycling. Shangchen is devoted to the field of industrial wastewater and has become a leading role in the industry after more than ten years of rapid development. The core business of the Company is concentrated in the field of industrial wastewater treatment, and covers pollution control fields such as river management, pyrolysis of domestic waste, heavy metal soil management, sludge reduction, waste acid and alkali recovery, and hazardous waste treatment. Shangchen is committed to providing customers with professional overall solutions, and has now formed a complete industrial chain of environmental pollution control throughout the entire life 。

1、What are the core technologies of surfac

2、What is the status of industrial wastewa

3、Heavy Metal Wastewater | Heavy Metal Was

4、Electroplating Wastewater | Electroplati

5、What are the core steps of industrial wa